News

- Home

- Medical Imaging Compliance Software | PerfectLum QA

Medical Imaging Compliance Software | PerfectLum QA

- September 13, 2025

- Sam Lee

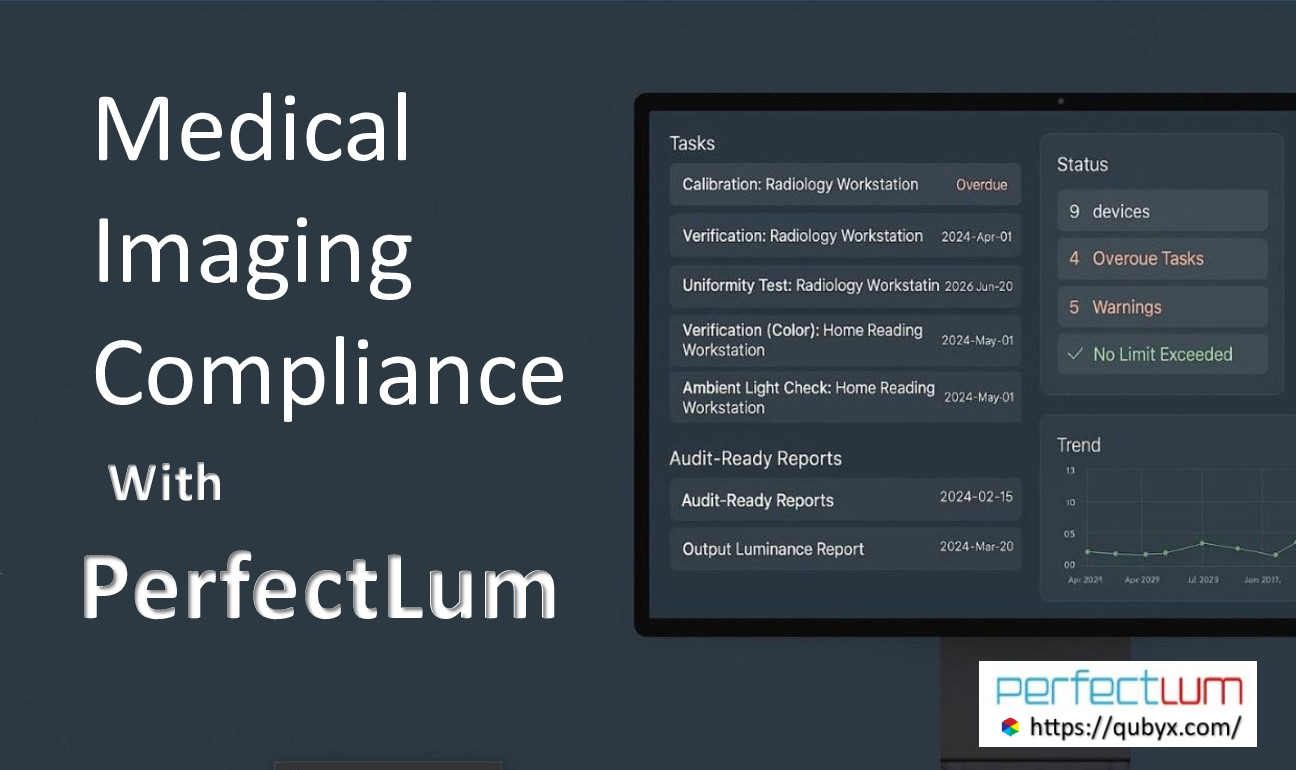

Medical Imaging Compliance Software | PerfectLum for Radiology & Teleradiology QA

In medical, imaging compliance isn’t paperwork—it’s patient safety, diagnostic confidence, and audit readiness. From grayscale accuracy to ambient light limits, regulators and professional bodies expect hospitals, imaging centers, and teleradiology practices to prove their displays and workflows meet standards—every day, not just at inspection time. That’s exactly where medical imaging compliance software earns its keep: it turns standards into schedules, measurements into dashboards, and findings into audit-ready reports.

Below is a practical guide to the moving parts—and where PerfectLum fits.

What Imaging Compliance Really Means in Imaging

Imaging Compliance spans people, processes, and technology. On the display quality side, typical references include:

- DICOM Part 14 GSDF (grayscale response)

- AAPM TG18 (test patterns & procedures)

- DIN 6868-157 / 6868-57 (acceptance/constancy concepts)

- IEC 62563-1 (image display performance)

- Payer, accreditation, or national requirements (e.g., mammography specifics)

Auditors and Quality Leads Want to See:

- Policies that define targets and frequency,

- Evidence that checks happened on time with approved instruments,

- Results against thresholds, and

- Remediation when something failed.

The Common Gaps (and Hidden Costs)

- Monitor drift slowly pushes luminance or grayscale response out of spec.

- Spreadsheet QA becomes unsearchable and incomplete across sites.

- Inconsistent frequency (missed constancy checks, ad-hoc acceptance tests).

- Audit panic—rushing to reconstruct logs, instrument serials, and sign-offs.

Imaging Compliance software fixes this by codifying policy, scheduling tests, guiding measurements, and centralizing proof.

What to Expect From Imaging Compliance Software

- Standards-based calibration & verification

- DICOM Part 14 GSDF calibration and verification with Just-Noticeable Difference (JND) tracking.

- Acceptance and constancy test templates aligned to TG18/IEC/DIN concepts.

- Measurement coverage

- Luminance response, maximum/minimum luminance (Lmax/Lmin), contrast, grayscale/ΔE (for color-capable workflows), uniformity, and ambient light checks.

- Scheduler & alerts

- Automatic task creation per device (daily/weekly/monthly/quarterly), reminders, and failure notifications.

- Asset inventory & roles

- Fleet view of all workstations, serials, locations, assigned policies, and role-based permissions (physics, QC techs, IT, radiologists).

- Audit-ready reporting

- Tamper-evident logs, trend charts, PDF/CSV exports, sign-offs, and remediation trails.

- Remote management

- Multi-site visibility (including home/telerad setups), with centralized dashboards and policy enforcement.

- Security & scope

- QA data only (no PHI images required for compliance tasks), local device agents, and export controls appropriate to your environment.

How PerfectLum Helps You Close the Imaging Compliance Loop

PerfectLum is purpose-built to operationalize display QA—so you can meet Imaging Compliance standards and prove it.

- DICOM GSDF Calibration & QA

Guides you through DICOM Part 14 calibration with supported probes, verifies grayscale response, and documents JND errors and allowable deviation. - Acceptance & Constancy Testing

Runs structured checks (e.g., luminance response, Lmax/Lmin, uniformity, ambient light), stores raw readings, pass/fail results, and references to the test pattern/procedure used. - Policy-Driven Schedules

Define modality-specific policies (e.g., more stringent luminance for mammography, different cadence for reading room vs. clinic). PerfectLum automatically schedules tests per device and notifies the right people. - Centralized Oversight for Distributed Fleets

One dashboard to see status by site, modality, and room—including home workstations—with drill-downs for failing metrics and overdue tasks. - Audit-Ready Packets

Generate PDFs/CSVs with timestamps, instrument IDs, test owners, thresholds, results, and remediation notes—exactly what auditors look for. - Works Across Platforms

Supports Windows and macOS environments, so IT doesn’t need parallel toolchains. - Fits the Real World

Supports a wide range of widely used measurement devices and realistic workflows (e.g., check ambient light before testing, verify uniformity after major moves).

Bottom line: PerfectLum turns calibration and QA from a one-off chore into a repeatable, measurable, provable program.

A Practical Implementation Playbook

- Map the Fleet

Inventory every diagnostic and clinical review display, including teleradiology/home readers. Record make/model, serial, location, use-case, and owner. - Define Policies by Use-Case

- Diagnostic radiology, mammography, ultrasound, surgical displays, ED/ICU review stations—each can have different targets and frequencies.

- Set luminance, GSDF tolerance, ambient light limits, and uniformity thresholds.

- Run Acceptance Tests

Baseline each device after installation or major service. Capture initial results in PerfectLum. - Set Schedules & Automate

Configure constancy checks (e.g., monthly grayscale verification, quarterly uniformity, semiannual ambient light). Turn on alerts for overdue or failed tasks. - Train the Team

Short role-based training: physics/QA leads on policy editing and reporting, technologists on running tests, IT on deployment and probe maintenance. - Remediate Faster

When a device fails, use PerfectLum to log corrective actions (recalibrate, replace, service). Track time-to-close and recurrence. - Report with Confidence

For audits or internal reviews, export device-level and site-level packets: schedules, results, trends, and sign-offs.

KPIs to Track (and Improve) | Imaging Compliance

- % Displays In Compliance (by site/modality)

- Average GSDF Deviation (JND error over time)

- Time to Remediate (failed → fixed)

- Calibration Drift Rate (how quickly devices move out of tolerance)

- On-Time Completion Rate (scheduled tests completed by due date)

- Ambient Light Non-compliance (incidents per quarter)

Sample Policy Language (Starter Template)

- Scope: All diagnostic and clinical review displays used for interpretation or critical care.

- Standards: DICOM Part 14 GSDF; applicable national/organizational guidelines (e.g., TG18, IEC 62563-1, DIN 6868-157).

- Measurement Instruments: Approved probes, calibrated per manufacturer guidance; serials recorded in PerfectLum.

- Acceptance Testing: Required at installation, relocation, major service, or display replacement.

- Constancy Testing: GSDF verification monthly; uniformity quarterly; ambient light quarterly (or after room changes).

- Thresholds: Define modality-specific luminance, contrast, tolerance limits, and ambient light maximums.

- Remediation: Recalibrate; if out of spec persists, remove from diagnostic use until corrected; document action in PerfectLum.

- Records & Reporting: All tests, results, sign-offs, and corrective actions maintained in PerfectLum; export for audits on demand.

(Always align with local regulations, accreditation bodies, and radiology leadership.)

FAQ

Do consumer displays ever qualify?

Sometimes—for non-diagnostic review—if they meet luminance, uniformity, and GSDF targets. PerfectLum will measure and document this; if they miss, you’ll know why.

Is this only about grayscale?

Grayscale is central to diagnostic imaging, but many workflows benefit from color QA (e.g., nuclear medicine, 3D, derm/ophthalmic). PerfectLum can track color metrics where relevant.

What about teleradiology?

Distributed reading is exactly where a centralized, policy-driven tool helps. PerfectLum schedules, guides, and records QA across homes, clinics, and hospitals—so Imaging Compliance standards are consistent.

Takeaway

Medical imaging compliance software transforms QA from reactive and manual into predictable, measurable, and audit-ready. With PerfectLum, you get standards-aligned calibration and verification, policy-driven automation, fleet-wide visibility, and one-click evidence—so radiologists can trust what they see, and quality leaders can prove compliance at any time.

At QUBYX, we don’t just enhance images—we redefine what image quality means for the industries that depend on it.

medical imaging compliance software, DICOM GSDF calibration, AAPM TG18 constancy tests, DIN 6868-157 compliance, IEC 62563-1 imaging standards, radiology display QA, teleradiology compliance software, diagnostic display calibration, medical QA software, imaging center audit readiness, radiology workflow compliance, display quality assurance software, PerfectLum medical imaging, compliance for mammography monitors, remote QA management, medical display calibration tool, healthcare imaging compliance, audit-ready QA software

Related Posts

- February 24, 2026

- News

What is AAPM TG270? A Practical Guide to AAPM TG-270

- February 24, 2026

- News

How to Calibrate a Display to DICOM GSDF with PerfectLum

- February 23, 2026

- News

Why Calibrate a Display to DICOM? And the Role