News

- Home

- Automated DICOM Compliance – The PerfectLum Feature That Saves Time and Lowers Risk

Automated DICOM Compliance – The PerfectLum Feature That Saves Time and Lowers Risk

- September 9, 2025

- Sam Lee

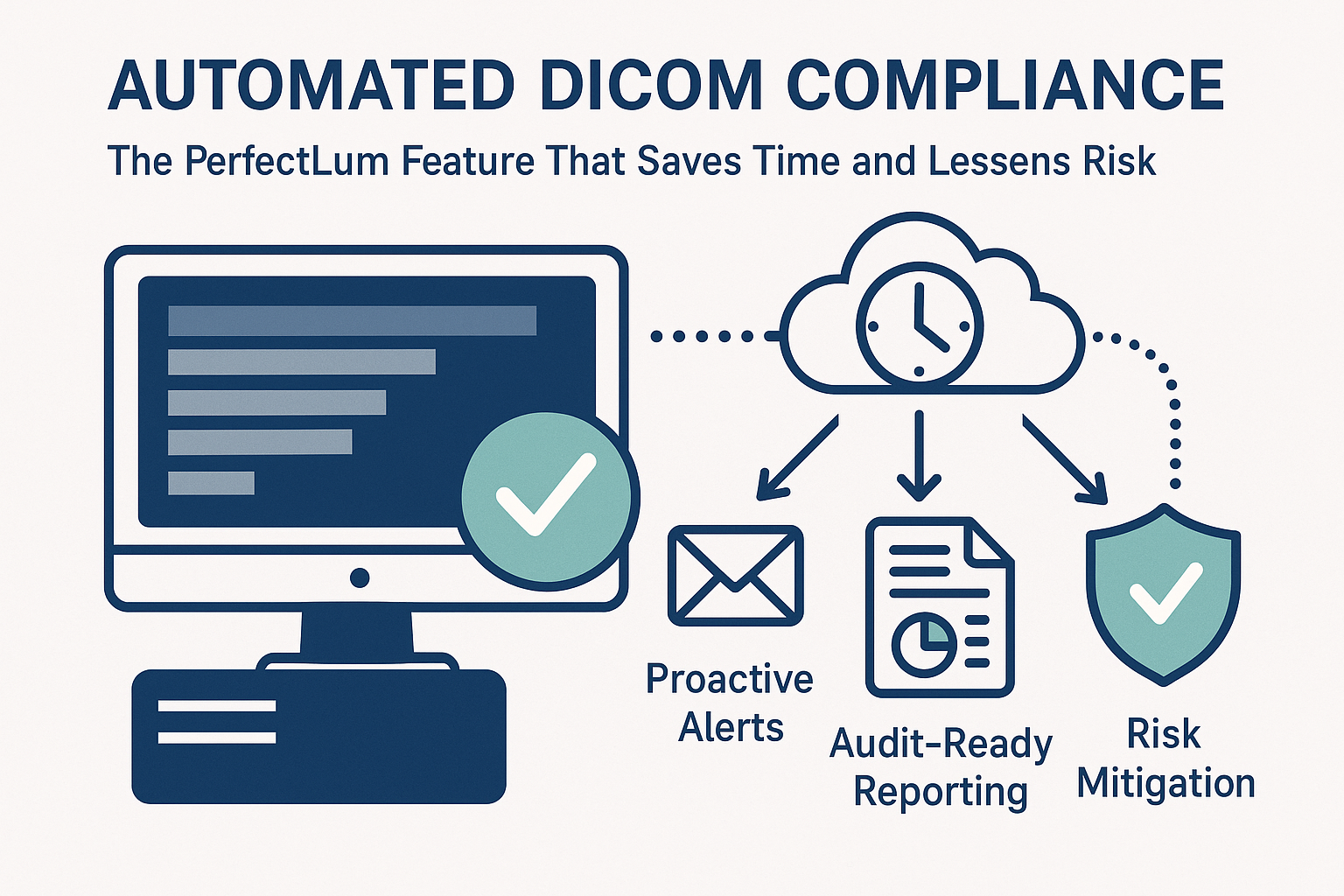

Automated DICOM Compliance: The PerfectLum Feature That Saves Time and Lowers Risk

When imaging teams talk about “compliance,” they’re talking about far more than paperwork. In radiology, mammography, dental, and teleradiology environments, compliance directly affects diagnostic confidence, accreditation status, and patient safety. Yet many organizations still rely on manual checklists and calendar reminders to keep diagnostic displays aligned to DICOM Part 14 GSDF and related guidelines—a process that is slow, error-prone, and hard to audit.

PerfectLum changes that equation. With Automated DICOM Compliance, PerfectLum turns time-consuming QA tasks into a predictable, policy-driven workflow that runs quietly in the background—catching issues early, generating audit-ready reports, and freeing your team to focus on clinical work.

Why DICOM Compliance Matters (and Why Manual Methods Struggle)

What “DICOM compliance” actually means.

In the context of displays, compliance means your monitors are calibrated and verified against the DICOM Part 14 Grayscale Standard Display Function (GSDF) so grayscale steps appear perceptually uniform. It also means your acceptance and constancy tests follow recognized procedures (e.g., AAPM TG18/TG270, DIN 6868-157, MQSA for mammography, ACR expectations), and that you maintain documentation proving ongoing performance.

Where manual QA breaks down.

-

Scheduling friction: Coordinators chase staff and devices across sites and shifts.

-

Human error: Steps get skipped, readings are mis-entered, or a failed check goes unnoticed.

-

Audit gaps: Reports are scattered across spreadsheets, screenshots, and email threads.

-

Downtime risk: Problems surface during reading sessions instead of being caught proactively.

Result: higher risk, higher costs, and more time away from patient-facing work.

What Is Automated DICOM Compliance in PerfectLum?

Think of it as an autopilot for display QA and documentation. You define the rules once; PerfectLum executes them automatically, consistently, and at scale.

Core capabilities:

-

Policy-driven schedules: Create profiles per modality or site (e.g., “Mammo – Weekly constancy, monthly uniformity”) and auto-assign to groups of devices.

-

Automated GSDF calibration & verification: Run calibrations and constancy checks to DICOM Part 14 GSDF with repeatable procedures and clear pass/fail thresholds.

-

Remote QA server: Centrally orchestrate tasks across single or multi-site networks; push schedules, receive results, and monitor status from a unified dashboard.

-

Proactive alerts: Get email notifications when a display drifts, fails, or misses a scheduled task—so you can intervene before clinical impact.

-

Audit-ready reporting: Generate time-stamped, immutable logs and compliance reports (device history, pass/fail trends, corrective actions) in clicks.

-

Role-based access: Let physics, IT, radiology managers, and QA staff see exactly what they need—no more, no less.

-

Flexible deployment: Use a hosted server for rapid start-up or install on-prem for tighter control and security policies.

-

Enterprise scalability: Manage hundreds or thousands of displays with consistent standards and centralized governance.

Bonus: In mixed color/mono environments, PerfectLum can handle color calibration workflows as well. With supported sensors and monitors, you can target tight color accuracy while keeping grayscale behavior aligned to GSDF.

How It Reduces Risk (Clinical, Operational, Regulatory)

-

Clinical assurance: Automated checks catch luminance drift and non-uniformity early, reducing the likelihood of sub-optimal image review.

-

Regulatory readiness: Standardized procedures and automatic logs simplify inspections (e.g., for ACR, MQSA-related monitor inspections, local regulations).

-

Operational stability: Issues trigger alerts—not surprises during peak reading hours.

-

Liability mitigation: Time-stamped records demonstrate due diligence and continuous quality control.

-

Workforce resilience: When staff changes or rotates, the system still enforces policies consistently.

The Time-Savings Equation (and Real-World ROI)

Manual workflows often require 10–20 minutes per display per month for checks, logging, and chase-down. At 150 displays, that’s 25–50 hours monthly—time that can be redirected to physics oversight, device optimization, or IT hardening.

With Automated DICOM Compliance:

-

Scheduling: Set once, apply to groups, and forget.

-

Execution: Runs after hours to minimize disruption.

-

Documentation: Reports compile themselves—no manual stitching.

-

Exception-only focus: Staff attention goes to the 5–10% of devices that truly need it.

Even conservative estimates typically show a 50–70% reduction in hands-on QA time, plus faster audits and fewer unplanned interruptions.

A Day-to-Day Flow With PerfectLum

-

Onboard displays: Install the agent, register the monitor/workstation, and capture baseline acceptance data.

-

Assign policies: Map each device to a policy (e.g., “CT Reading Rooms,” “Mammo QA,” “ED triage”).

-

Automate schedules: Push nightly/weekly/monthly checks; align to standards (AAPM TG18/TG270, DIN 6868-157, MQSA expectations).

-

Run unattended: Calibration and constancy tests execute off-hours; users aren’t interrupted.

-

Watch the dashboard: Green = good. Yellow/red indicates drift or a failed check.

-

Act on alerts: Review root cause (sensor, environment, settings), recalibrate, and note corrective action.

-

Export reports: Audit-ready PDFs/CSV for DICOM compliance reviews, accreditation, and internal QA committees.

Built for Modern Imaging Teams

Radiology departments: Standardize QA across modalities (CR/DR, CT, MR, US, IR) and reading rooms.

Mammography services: Support rigorous constancy checks and documentation aligned with MQSA-related monitor expectations.

Dental imaging & oral radiology: Keep smaller fleets compliant without adding admin overhead.

Teleradiology networks: Enforce uniform QA policies across dispersed sites and home workstations.

Multisite health systems: Centralize governance; compare performance across campuses and vendors.

Security & IT Considerations

-

On-prem or hosted: Choose your model to satisfy data residency and security requirements.

-

Least-privilege access: Role-based permissions scope what each user can see and do.

-

Change tracking: Every calibration, check, and corrective action is time-stamped for traceability.

-

Sensor & vendor flexibility: Works with supported sensors and a broad range of medical-grade and COTS displays.

Frequently Asked Questions About DICOM Compliance

Is DICOM GSDF calibration alone enough for compliance?

Not by itself. GSDF calibration is essential, but most programs also require acceptance testing, periodic constancy checks, environmental considerations, and documentation aligned to recognized guidelines (e.g., AAPM TG18/TG270, DIN 6868-157, MQSA contexts, ACR expectations). PerfectLum automates both the technical procedures and the paper trail.

What happens if a display fails a check?

PerfectLum flags it in the dashboard and sends alerts. You can enforce workflows (e.g., automatic recalibration, technician ticketing, or escalating notifications) and record corrective action for audit completeness.

Will automation disrupt clinical work?

No—schedules typically run during low-usage windows. You can throttle or defer tasks for urgent reading sessions, and the system maintains logs regardless.

How do we prove DICOM Compliance to inspectors?

Generate device-level and fleet-level reports showing schedules, calibrations, constancy results, pass/fail history, and corrective actions—exportable for audits in minutes.

The Bottom Line

Automated DICOM Compliance with PerfectLum transforms QA from a manual burden into a reliable, scalable, and auditable process. You reduce clinical and regulatory risk, accelerate audits, and return dozens of hours per month back to your team—without compromising diagnostic quality.

Ready to modernize your imaging QA?

Adopt PerfectLum’s automated approach and standardize compliance across every site, modality, and workstation.

At QUBYX, we don’t just enhance images—we redefine what image quality means for the industries that depend on it.

SEO Keywords

Automated DICOM Compliance; medical imaging compliance; PerfectLum features; risk mitigation; DICOM Part 14 GSDF; AAPM TG18; AAPM TG270; DIN 6868-157; MQSA monitor inspection; display QA software; remote QA server; audit-ready reporting; radiology QA; teleradiology compliance, DICOM Compliance,

Related Posts

- February 24, 2026

- News

What is AAPM TG270? A Practical Guide to AAPM TG-270

- February 24, 2026

- News

How to Calibrate a Display to DICOM GSDF with PerfectLum

- February 23, 2026

- News

Why Calibrate a Display to DICOM? And the Role